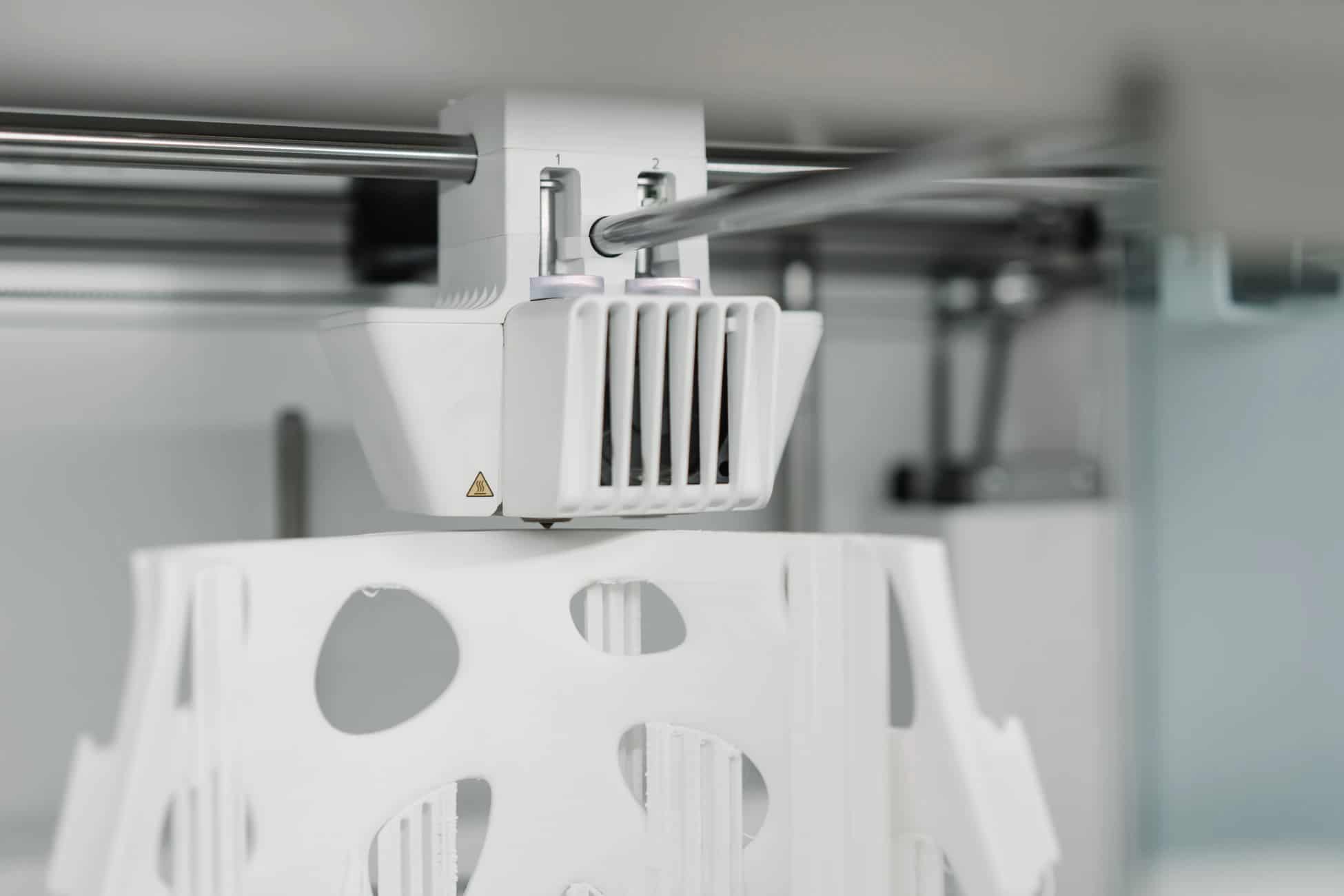

Seamless Manufacturing & Processing!

Manufacturing Applications:

Cast Film

Cast film is made by depositing a layer of plastic, either molten, in solution, or a dispersion, onto a surface, solidifying, and removing the film from the surface. Films can also be made from Extrusion.

Compression Molding

The method of molding a material already in a confined cavity by applying pressure and usually heat. This process is often used in closure manufacturing.

Extrusion Molding

A process in which heated plastic is forced through a shaping orifice (a die) in one continuously formed shape, as in film, sheet, rod, or tubing.

Injection Molding

The process of forming a material by forcing it, in a molten state and under pressure, into the cavity of a closed mold. This is the most common production method used with Plant-based Plastics.

Rotational Molding

A molding process where a pulverized resin is placed in the mold at high rotational speed to ensure resin dispersion. Once in place, the resin is baked in the mold to form the usable part. This process is used often to manufacture large, heavy plastic parts.

Thermoforming

A forming process in which a heated plastic sheet is molded through heat and pressure and trimmed to create a usable product. This process is often used in multi-layer packaging.

Transfer Molding

A method of forming articles by fusing a plastic material in a chamber and then forcing the mass into a hot mold where it solidifies.

Vacuum Forming

A forming process in which a heated plastic sheet is drawn against the mold surface by evacuating the air between it and the mold.

We eagerly welcome manufacturers to join us on the journey to Utopia.

using Utopia Plastix resin…from the manufacturer perspective…